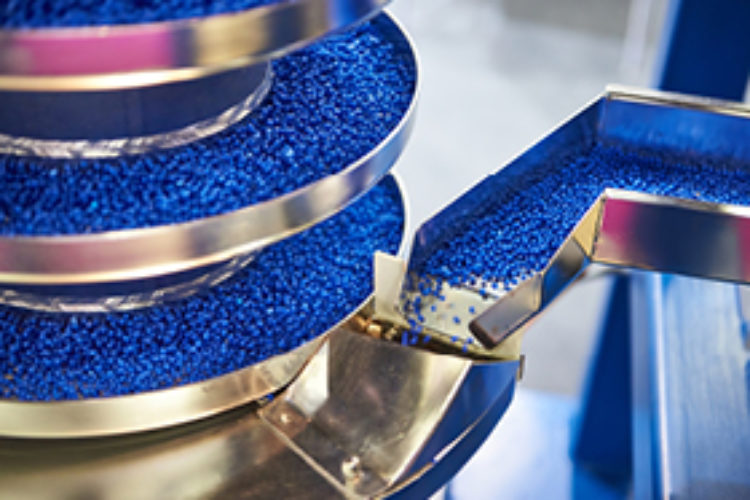

PSA (lösungsmittelfrei)

Lösungsmittelfreies Mastizieren und Homogenisieren mit den Anlagen von ENTEX. Zielgerichtete und exakt gesteuerte Reaktionen garantieren Ihnen gleichmäßige Homogenität und Viskosität des Austragsmaterials.

Anwendungsspektrum

Ein kurzer Überblick über die Vielfalt der Anwendungsgebiete unseres Planetwalzenextruders:

Lösungsmittelfreies Mastizieren und Homogenisieren mit den Anlagen von ENTEX. Zielgerichtete und exakt gesteuerte Reaktionen garantieren Ihnen gleichmäßige Homogenität und Viskosität des Austragsmaterials.

Zielgerichtete Aufschmelzbarkeit unterschiedlicher Rezepturbestandteile, extrem kurze Aufbereitungszeit von nur wenigen Minuten, effektives Abkühlen auf kurzer Strecke, scherarmer und materialschonender Aufbereitungsprozess. Dafür steht der Planetwalzenextruder.

Innovative Misch- und Reaktionsanlagen von ENTEX verbinden mehrere Prozessschritte miteinander und verkürzen so das Verfahren erheblich. Temperaturführung, Druckmessung und Entgasung kommen in einem einzigen zusammenhängenden Prozessaufbau zusammen.

Kontinuierliche Verarbeitung, schonende Verarbeitung temperatursensitiver Materialien, exzellente Materialqualität, Entgasung auf höchstem Niveau, effiziente Selbstreinigung, vielseitige Verarbeitungsmöglichkeiten. Das sind die Extruder für (Bio-)Kunststoff von ENTEX.

Hervorragende Homogenisierung, präzise Temperaturführung, planvolle Prozessreaktionen, effektives Entgasen, schonender Aufbereitungsprozess und effektives Abkühlen sind unser "Think Green". Mit ENTEX schon heute an die Generationen von morgen denken.

Egal ob Böden oder Gartenmöbel: Wenn thermisch empfindliches Material compoundiert und granuliert werden soll, braucht es die richtungsweisende Technologie von ENTEX.

Das Herstellen teurer Dryblends hat ein Ende. Sparen Sie Energie, Zeit und Kosten mit der kontinuierlichen Direktextrusion von ENTEX. Geeignet auch für Hart-PVC.

Verarbeiten aller Rezepturbestandteile in nur einem Schritt durch eine optimale Temperierung. Setzen Sie auf kontinuierliche statt diskontinuierlicher Verarbeitung mit durchgängig exzellenter Materialqualität bei einer Vielzahl an Verarbeitungsmöglichkeiten.

Technologischer Vorsprung dank schnell erreichten Zielviskositäten, optimaler Verweilzeitsteuerung und Entgasung auf höchstem Niveau. Innovative, reaktive Extrusionsprozess-Anlagen von ENTEX für ihre Spitzenprodukte.