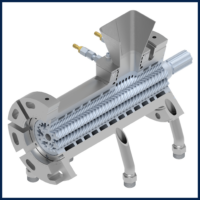

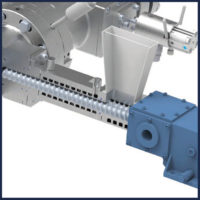

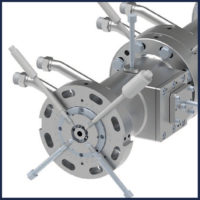

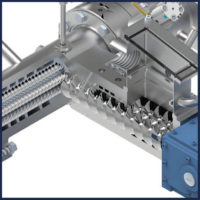

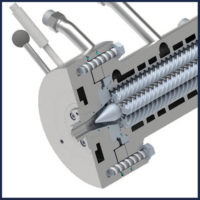

Structure and Components

Modular and individually adaptable

Optimise your production processes or accelerate the development of new products. ENTEX’s unique and innovative modular system offers unprecedented economic and technical benefits. Its modular construction allows as many as 8 roller cylinders to be connected in series.