The ENTEX extrusion line

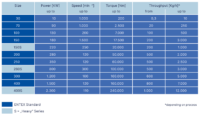

The configuration of the Planetary Roller Extruder is tailored to the individual production process. Thanks to a modular system that is able to accommodate each individual step in the process – such as material feeding, melting, mixing in, homogenisation, degassing, etc. – and corresponding peripherals, Planetary Roller Extruders can be used to perform, optimise or replace a wide range of production processes in the adhesives, plastics, rubber, chemicals and food industries. The modular concept makes a variety of process section lengths possible for all PRE unit sizes listed below. The maximum length in each case depends on the unit size, process, expected central spindle torques, and the materials used, and must be individually determined. Formulations are administered and process parameters set using the ergonomic control system, while the process is monitored by integrated sensors.